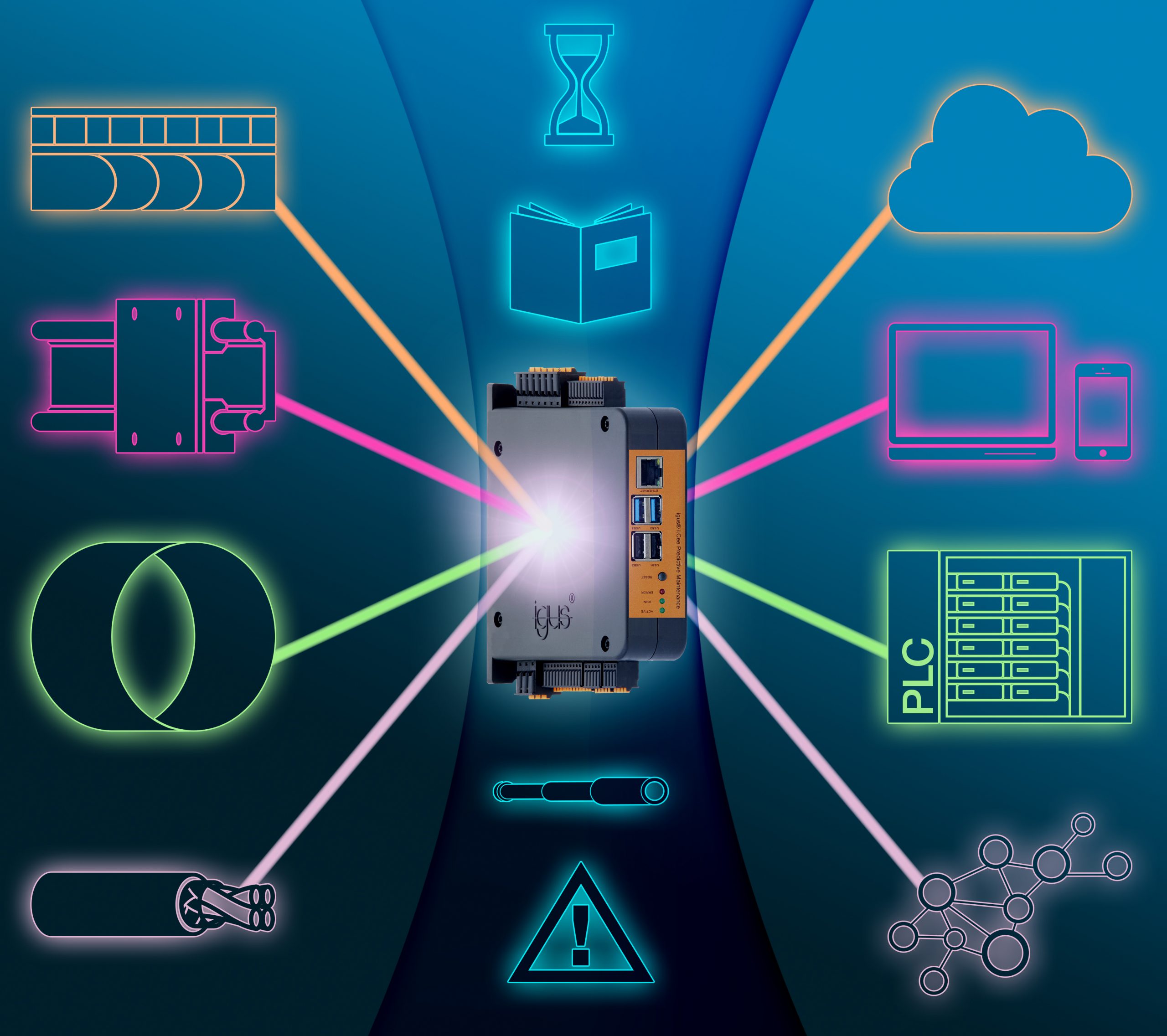

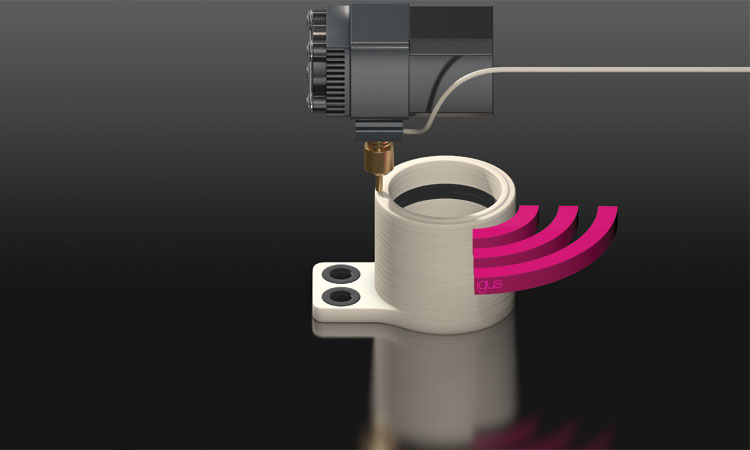

iComm Box: An All-in-One System for Next-Generation Condition Monitoring

igus® Introduces a New Communication Module for Seamless Condition Monitoring Integration June 13, 2024 – The iComm Box, a new communication module from igus, facilitates the integration of i.Sense sensors with the superwise service,...