iComm Box: An All-in-One System for Next-Generation Condition Monitoring

igus® Introduces a New Communication Module for Seamless Condition Monitoring Integration

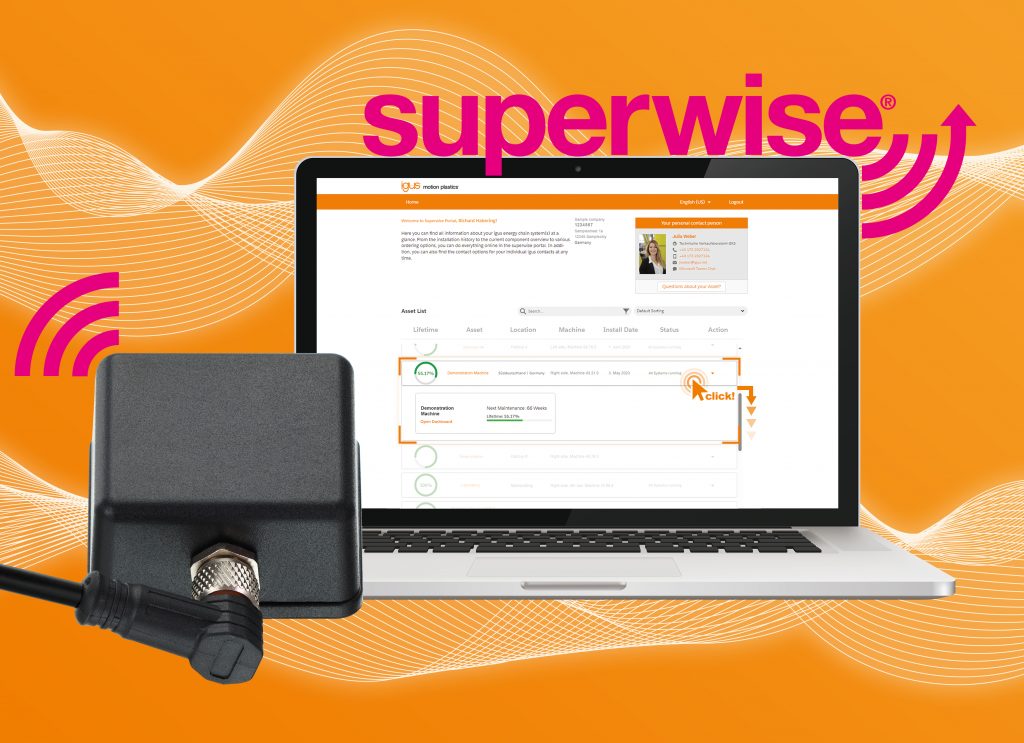

June 13, 2024 – The iComm Box, a new communication module from igus, facilitates the integration of i.Sense sensors with the superwise service, enabling cost-effective, rapid, and reliable real-time condition monitoring. The system leverages intelligent algorithms to provide detailed status analyses of monitored machines and systems. Real-time information is displayed on the superwise dashboard, optimizing monitoring and control. The cost of data transmission is included in the product price.

Intelligent sensors from the i.Sense series, used for several years by igus, monitor moving machine components such as energy chains, cables, linear guides, plain and spherical bearings, and slewing ring bearings. These sensors can trigger messages or automatic system stops in case of anomalies, thus preventing costly damage.

“The new communication module now opens up the cost-effective and simple option of expanding the functionality of these sensors,” explains Richard Habering, Head of the smart plastics Business Unit at igus.

The module connects the sensors to the superwise service, thus ensuring fast and reliable data transmission. Reports are saved with measured values in the igus i.Cee portal and can be later evaluated for diagnostic purposes.

Intelligent algorithms use sensor data to calculate movement profiles of components like energy chains. This detailed analysis allows for precise condition predictions. Real-time information on service life, maintenance recommendations, and anomalies are clearly displayed on the superwise dashboard.

Fast return on investment with maximum security

Potential users include companies in the process industry, such as sewage treatment plants, concrete works, container cranes in ports, and the manufacturing industry, including automotive manufacturers. The new solution promises a fast return on investment by optimizing maintenance management and preventing expensive downtime.

“One minute of system downtime costs up to $50,000 in the automotive industry. If we can save just a few seconds with the iComm Box, which is quickly achieved, the investment has already paid off,” emphasizes Habering.

The i.Sense EC.P sensor demonstrates the iComm Box’s functionality by measuring tensile and shear forces in the energy chain. The data is transmitted via a cable to an evaluation module in the control cabinet, which can be connected to the PLC to trigger an automatic system stop if necessary. A new feature allows this evaluation module to connect to the iComm Box via an additional cable. The communication module then sends the data to the superwise dashboard via a secure, encrypted mobile network, separate from the customer’s TCP-IP network. The purchase of the module includes a ten-year data flat rate.

In the personalized dashboard, customers can view the remaining service life of networked components as a percentage and determine the ideal time for the next maintenance. The dashboard’s intuitive design simplifies monitoring. If companies lack time to monitor systems themselves, igus can assume this responsibility through the superwise service. The i.Cee portal, connected to the igus CRM system, ensures that sales employees are informed of all reports and automatically receive corresponding tasks. This proactive approach allows for fast deliveries in case of plant shutdowns, eliminating the need for customers to monitor the dashboard themselves.

With the iComm Box, igus offers an all-in-one system designed to meet the challenges of Industry 4.0. It relieves customers’ human resources and enhances productivity during skilled labor shortages.