STS container cranes: fit for the future thanks to the new igus heavy-duty rol e-chain

P4HD.56.R: suitable for long travels, high speeds, heavy cable loads, and Industry 4.0

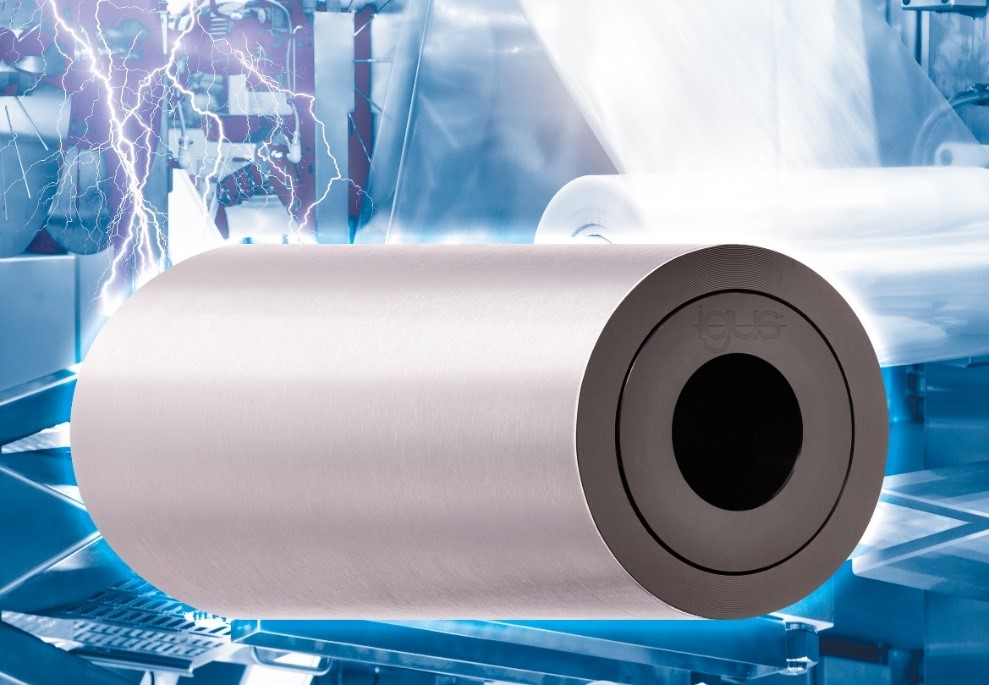

17 AUGUST 2022 – igus®, the world leader in motion plastics and moving cable management systems, has introduced the rol e-chain® P4HD.56.R – a new heavy-duty energy chain cable carrier designed for long travels, high speeds, heavy cable loads, and Industry 4.0.

Over the past 25 years, container ships have grown larger and larger as shipping companies continue to seek economies of scale and fuel efficiency. Currently, the world’s largest container vessel is the Ever Alot, with a carrying capacity of 24,004 containers and measuring 400 meters long by 61.5 meters wide, with a draft of 17 meters.

Bigger ships mean bigger cranes

The recent development of ultra-large container vessels (ULCV) is changing the industry and putting new pressure on terminals to provide deeper drafts and taller ship-to-shore (STS) cranes to service these mammoth containers efficiently.

This enlargement also affects the cable carriers that guide the energy and data cables for the crane trolley. They have to withstand unprecedented loads: travels of over 130m, cable weights of up to 10kg/m (over 20kg/m for motor-driven trolleys), and accelerations of more than 1m/sec2 are standard for Triple E-class STS cranes. In other applications, travel distances of several hundred meters, cable loads of up to 50kg/m, and accelerations of 8m/sec2 and more can be achieved.

“We have developed the new P4HD.56.R heavy-duty e-chain cable carrier for these extreme requirements,” says Theo Diehl, Industry Manager for Cranes at igus. “The e-chain is particularly robust and, thanks to its sensor technology, prepared for Industry 4.0 trends, such as predictive maintenance. This combination significantly increases STS crane reliability.”

The heavy-duty e-chain is to run trouble-free for up to 15 years

The engineers have developed special design features to achieve a long service life in STS cranes under high loads.

“A special fork-tab principle ensures even greater stability at higher additional loads, while a pin/bore connection made of tribologically optimized plastic minimizes wear,” says Diehl.

Furthermore, rollers are mounted in the inner radius of the chain links. As the e-chain travels, the upper run rolls on the lower run instead of sliding. Thanks to the low coefficient of friction, payload, and acceleration can be increased without changing the push/pull force. Long-term tests in igus’s in-house laboratory prove that P4HD.56.R, the heavy-duty design, achieves a 50% longer service life than the standard P41.56R variant.

“Our goal is for the e-chain systems to run on any STS crane for up to 15 years – trouble-free and with minimal maintenance,” says Diehl.

The rolling movement also reduces the required drive energy by 57% – another advantage in times of increasing energy costs. Since crane systems also require robust cables that can be used to achieve long travels with high dynamics, igus also offers CFCRANE. This chainflex® cable range has been developed explicitly for crane applications.

Fit for Industry 4.0

But the new P4HD.56.R is not only robust, durable, and energy-saving. The heavy-duty energy chain is also suitable for Industry 4.0. For example, it allows predictive maintenance with the help of i.Sense® monitoring sensors. The chain link status can be continuously transmitted to the i.Cee:plus communication module. i.Cee allows usage-based and condition-based maintenance, extending inspection intervals.

Maintenance is necessary only when the system sends a signal to that effect. Operators of STS cranes can use the i.Cee system to significantly increase system availability and extend energy chain service life. Holiday shut-downs and other planned downtimes are automatically taken into account in the i.Cee service life calculation and the forecast is constantly checked with sensors.

All these advantages do not limit usable inner width because the condition sensors and their electronics are integrated into the rol e-chain links to save space. No additional cables are necessary because data is transmitted via radio.

“The new P4HD.56.R-series e-chains meet all the requirements that apply to STS cranes of the next generation and the generation after that,” says Theo Diehl.

To learn more about the P4HD.56.R rol e-chain, click here.