igus robot control software: free simulation and cost-effective control of robots

Fast entry into Low Cost Automation using a digital twin in intuitive robot control

May 13, 2020 – igus has developed control software for its Low Cost Automation solutions that allows users to easily program their robots.

igus robot control is available online, free of charge, and offers the user an easy introduction to automation. igus, based in Germany, runs its North American operations out of Providence, R.I.

With the new software, different robot kinematics can be programmed and controlled. A digital twin simulates the movements. This allows the user to program a suitable solution before purchase. The robot hardware, for example, a linear robot with switch cabinet, is offered by igus for approximately $5,400.

Multiple Uses for Robots

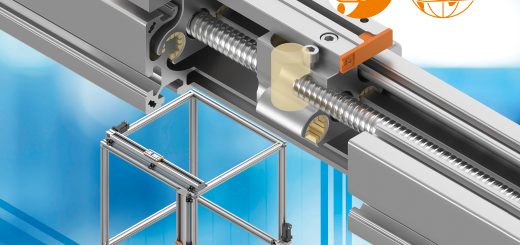

Picking up goods from a box, helping to take samples and dispensing items from a machine can all done by robots. Whether it is articulated arm robots, delta robots or linear robots, igus has all three kinematics as Low Cost Automation solutions in its portfolio. To enable users to try out in advance which robot is best suited for their application, igus now offers igus robot control, a software for the simulation and programming of all igus robots.

“As a mechanical engineering company, we are very familiar with the different kinematics, so the next logical step for us was to develop a correspondingly simple and intuitive robot control system,” says Alexander Mühlens, head of automation technology at igus GmbH. The software is available online free of charge and license-free.

In the software there is a digital twin for all igus robots, which can be simulated and taught like the real robot. The robot control system is also used later to program the robot intuitively. Every program can be applied to the real robot afterwards. The complete hardware package — for example, a drylin linear robot with an integrated control system in the switch cabinet — is available for about $5,400.

Easy programming of robots

With igus robot control, the user can freely move all axes of the digital twin via a 3D interface. By means of a teach-in function the robot can be programmed quite easily, even without a robot connection.

To do this, the user must manually move the robot to the desired position and define how it is to be moved. The process is repeated until the desired motion profile is created. Matching end effectors, such as grippers, are easy to add and the tool center point adjusts automatically.

Virtual boxes can also be installed, for example, to prevent the robot from colliding with a machine. The igus robot control can also be connected to a higher-level control system, either via interface communication with Digital IO or via Ethernet communication using an IP address. The igus developers want to expand the control system even further: “In the future, we want to offer cloud services such as vision integration, remote commissioning and also online training for a small cost, which the customer can book. Further services such as image evaluation via webcam or bin picking solutions are planned as cloud-based solutions,” says Mühlens.