igus develops first certified robotic energy supply system for dry cleanrooms

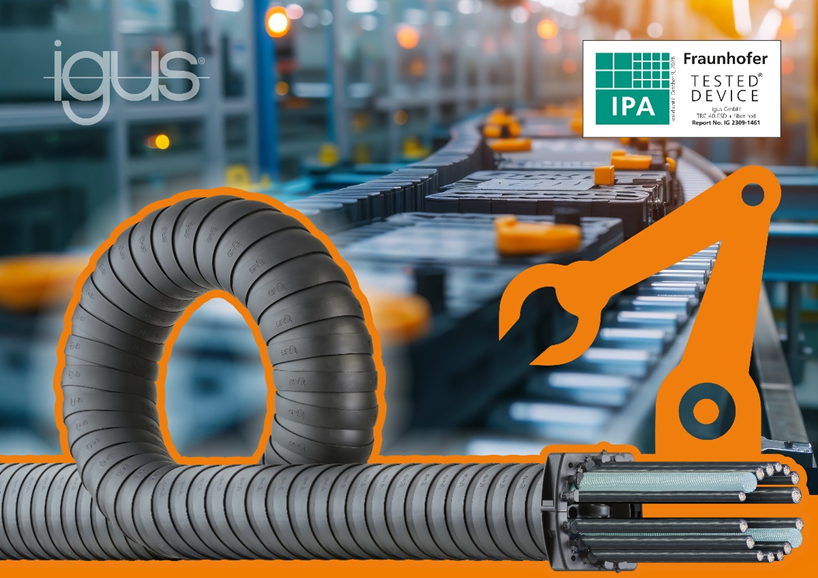

Maximum safety in battery production: triflex® R TRC made of the material ESD receives the best possible certification for dry cleanrooms for ISO Class 4-5

June 21, 2024 – With the growing demand for electric cars, the need for high-quality lithium-ion batteries is also increasing. For this reason, they should ideally be manufactured in dry cleanrooms with minimal humidity and as little particulate matter as possible. At the same time, this environment must be automated because people are not allowed to spend long periods of time in dry cleanrooms. To ensure safe and reliable energy supply to robots, motion plastics specialist igus has developed triflex R TRC: the first robot energy supply system with a certification for dry cleanrooms from Fraunhofer IPA for ISO Class 4-5.

For several years now, igus has been demonstrating what a robot energy supply system that functions reliably at high speeds and ever smaller rotation radii can look like with triflex R: a three-dimensionally movable energy chain made of high-performance plastic for multi-axis robots. However, special areas of application, such as battery production, are placing higher and higher demands on the machine components used. With triflex R TRC and the associated fiber-rod module, igus now offers the first robot energy supply system certified for applications in dry cleanrooms. It was specially developed for the cable supply of industrial robots used in battery cell production. The additional ESD certification extends the application possibilities.

ESD material for double safety

The system essentially consists of two components: an energy chain that can move along three dimensions and a fiber-rod module. The e-chain is a closed version of triflex R, which consists entirely of dissipative ESD material, including connection elements with strain relief. This means that there is no risk of damage to ESD-sensitive parts due to abrupt discharge.

“We decided to manufacture triflex R TRC from ESD material right from the start as this is required even more frequently in battery production than suitability for dry cleanrooms,” explains Matthias Meyer, Head of triflex e-chains and Robotics Business Unit at igus. “Our high-performance plastic igumid ESD has been tested with over 10 million cycles in our in-house laboratory and has been used successfully in a wide variety of applications for years.”

With triflex made of igumid ESD, customers benefit in two ways: they save costs as the material is now part of the standard product range, and increase system safety thanks to material and product that has already been tried and tested over many years. igus also has other ESD chains in their standard product range. Another advantage of igus high-performance plastics is their integrated solid lubricants, which means they do not require any grease, which would harden immediately in the dry cleanroom.

Quick and simple assembly due to prefabricated modules

In addition to the energy chain, triflex R TRC also consists of a fiber-rod module. The system is similar to a fishing rod. Two integrated fiberglass rods serve to stabilize the energy chain up to the 5th axis and prevent contact between the robot and the energy chain. This enables a virtually non-contact production process so that no particles are generated during the rotational movements. The prefabricated modules also allow for a quick and easy installation. As there are no points of contact, the energy supply system is also easy to use with other, separately certified products in the dry cleanroom, which gives the customer greater flexibility.

Tests passed with the best possible result

The TRC.40 was tested in a dry cleanroom at Fraunhofer IPA with a dew point of -40°C, which corresponds to a relative humidity of less than 1% at room temperature (22°C). Following the tests, the complete system consisting of chain and fiber-rod module was the first product of its kind to receive ISO Class 4 certification – and thus the best possible result with the current state of the art. Only with faster movements (v = 2.0m/s // a = 4.0m/s²) does the system achieve ISO Class 5.

In addition to triflex R TRC, the E6.29 energy chain from igus was the first solution certified for dry cleanrooms to achieve the best possible ISO Class 4 result last year. Both energy chains, therefore, fulfill the highest requirements for use in dry cleanrooms. Learn more about triflex R TRC here: https://www.igus.com/news/dry-cleanroom-robotic