igus presents new slewing ring bearing made of wood and plastic

Sustainability meets innovative technology – igus introduces new slewing ring bearings made of WPC

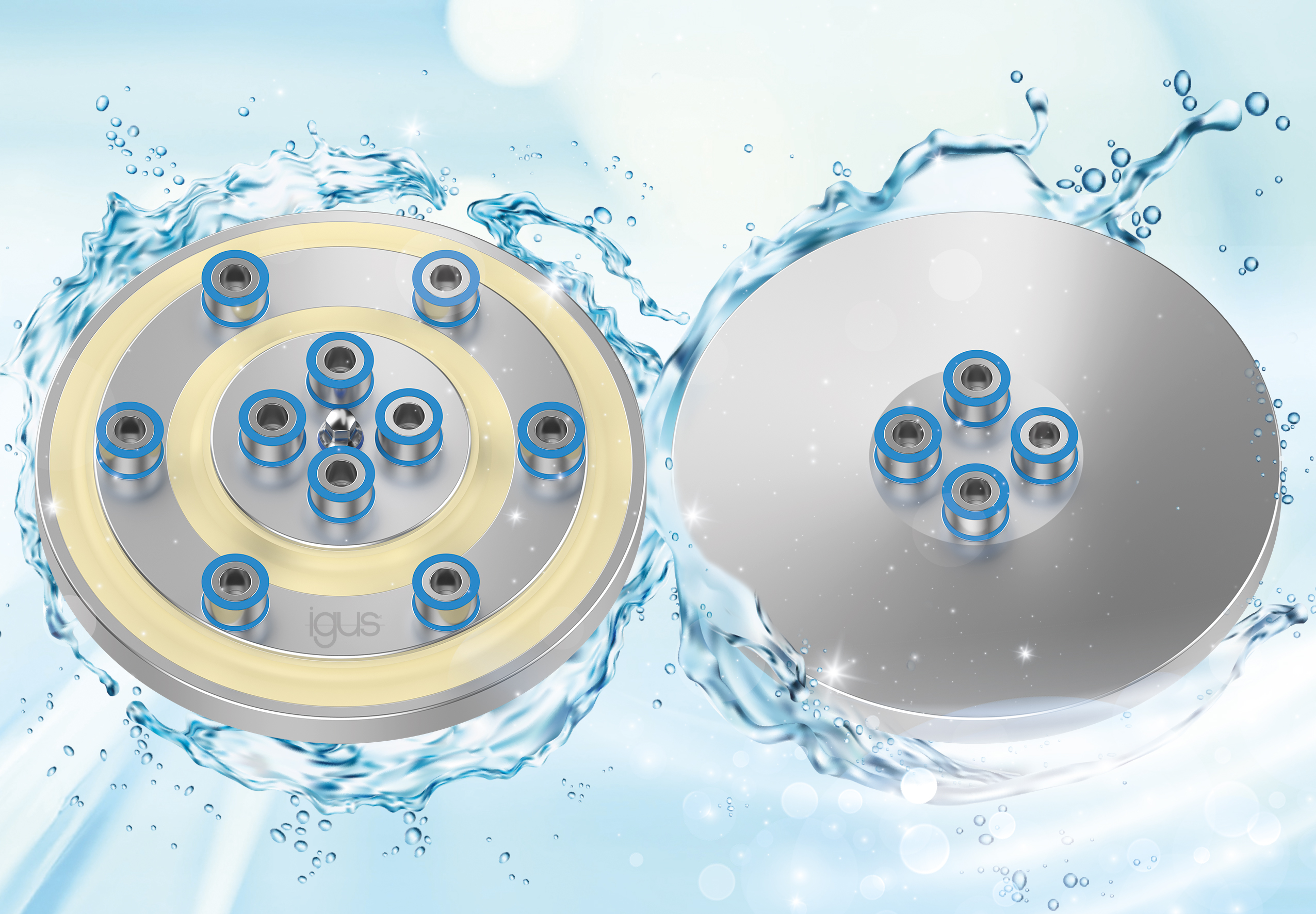

May 3rd, 2024 – The global leader in motion plastics, igus®, is expanding its broad range of PRT slewing rings with a new wood-plastic composite (WPC) bearing.

With the introduction of the new PRT-02-30-WPC, igus is taking another step forward in integrating renewable raw materials in industrial production. By incorporating 50 percent wood and 50 percent high-performance plastics, igus customers receive a cost-effective and lubrication-free slewing ring bearing. It balances strength, durability, and environmental friendliness with a proven low CO2 footprint.

“As a plastics expert, we are now venturing into the wood sector. Last year, we presented wooden shafts as possible mating partners for our linear guides for the first time. This year, we are integrating the wood directly into our products,” explains Marc Trenkler, Product Manager for Slewing Ring Bearings at igus GmbH.

Here, igus can rely on its proven injection molding. The new PRT consists of WPC, a mixture of wood fibers, and iglide® high-performance plastics. The materials incorporate solid lubricants, making the slewing ring bearing smooth-running, lubrication-free, and maintenance-free. Both the housing and the component are made of the WPC material. The wood content gives the bearing a natural look, and it only takes four screws to connect the two parts.

Cost-effective, low CO2 footprint, tried and tested

Developed specifically for the standard installation size, PRT 02, the slewing ring bearing from igus is an equally priced alternative to the cost-effective PRT made of solid plastic without compromising performance. It allows for easy adjusting, for example, in furniture technology, while offering a robust design that fulfills the requirements of various applications.

A unique feature of this new product is its extremely low CO2 footprint of just 0.0577 kilograms. By comparison, the PRT-02-30-ECO, which is already made from 97 percent regranulate, has a CO2 equivalent of 0.819868 kilograms.

To ensure the reliability and performance of the new slewing ring bearing, it was subjected to extensive tests under actual conditions in the 41,000-square-foot igus laboratory in Cologne, Germany. These analyses confirm the high quality and reliability of the product under various operating conditions.