Swimming Pool on Demand

Conmag Engineering transforms a terrace into a pool with the help of corrosion-resistant igus linear technology and saves $34,000

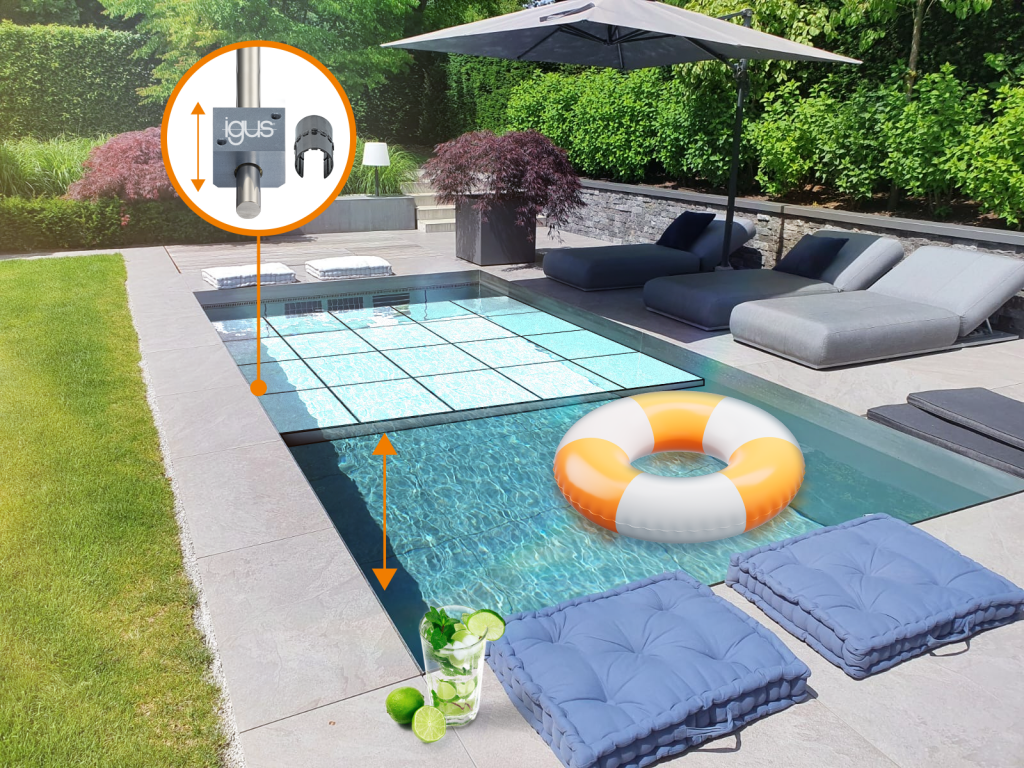

26 September 2023 – With the push of a button, a luxury swimming pool can be transformed into a walkable terrace. The key is a moving pool bottom from Conmag Engineering. But what linear technology works reliably and with little maintenance underwater? The engineers found the answer at igus, saving around $34,000 per system in the process.

When the temperature hits 100 degrees Fahrenheit, many people with small backyards find themselves sitting on their terraces, dreaming of a swimming pool. The solution from the Austrian company Conmag Engineering GmbH is a pool that is simultaneously a terrace. Its centerpiece: a mobile pool floor. In its uppermost position, it is stable enough for walking. However, when the owner no longer wants to sit in a deckchair and would instead take a dip in the pool, pressing a button is all it takes. The bottom descends to a maximum depth of 1.5 meters, exposing the water, which is already at a pleasant temperature. The floor has a ten-centimeter insulating layer on its underside to minimize heat loss. An integrated counter-current system even allows for a brisk swim in place – without having to continuously reverse direction.

Hard-to-reach linear technology must be maintenance-free

As simple and elegant as the Austrian swimming pool may appear, building the moving bottom was a technical challenge.

“The core competence was implementing a linear movement that was as constant, precise, and reliable as possible,” says Gerhard Rosskogler, Product Manager for High-Pressure Technology at Conmag. “When the bottom lowers, the aim is to keep water displacement forces as low as possible to ensure sustainable design without endangering system strength. And since the entire mechanism is underwater and difficult to access, all bearings must be maintenance-free and as low-wear as possible.”

igus linear guidance works without lubrication and is chlorine-resistant

“The igus experts gave us expert advice and made processing very quick,” says Rosskogler. “We immediately received free component samples and were able to start a test set-up quickly. This meant that we had a much longer test phase and were ultimately able to give the customer a mature product.”

The adjustment mechanism now works as follows: Threaded spindles are installed in all four corners of the pool. The floor moves up and down via them – securely guided by drylin® R series linear guides from igus with corrosion-resistant stainless-steel shafts, mounted on drylin OXUM-06 housing bearings made of anodized aluminum. XUM plastic plain bearing strips made of igus’ iglide X polymer provide lubrication for low-friction movement. The strips are resistant to high loads and chemicals, have low moisture absorption, and are wear-resistant under water.

Cost reduction of around $34,000 per pool

Thanks to linear technology from igus, Conmag Engineering has achieved several things at once.

First, the maintenance requirement for the adjustment mechanism is almost zero due to microscopic solid lubricants integrated into the plastic plain bearing strips that enable smooth, dry running without external lubricants. Therefore, there is no risk of grease or oil contaminating the water.

Second, all mechanism components also work reliably when in constant contact with water and chlorine.

“The combination of stainless steel and high-performance plastics makes corrosion unthinkable,” says Michael Hornung, Product Manager for drylin Linear and Drive Technology at igus. “In addition, the plastic absorbs very little moisture. This guarantees reliable, maintenance-free operation for many years.”

“With igus linear technology, each pool costs around $34,000 less than previously,” added Rosskogler.