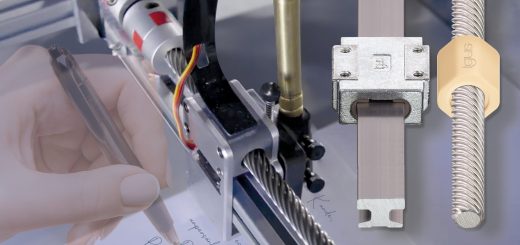

Small investment with a big effect: new contactless monitoring of igus® cables in e-chains

| i.Sense CF.D sensors use high-frequency technology to detect defects in bus and data cables, preventing expensive system downtimes. |

December 9, 2021 – igus®, one of the worldwide leaders in predictive maintenance, has introduced the latest generation of monitoring sensors that check the electrical condition of chainflex® cables in e-chain systems without contact or intervention in the existing harnessing.

The company’s i.Sense CF.D monitoring sensors allow real-time monitoring without extra cores and, in combination with the new i.Cee: plus II evaluation module, allows even more efficient predictive maintenance for protection against expensive system failures.

The latest CF.D generation facilitates the entry into predictive maintenance of chainflex® bus and data cables in igus® e-chain systems. The smart system consists of two sensor units clipped onto the cable before and after the chainflex® cable to be monitored. They are small enough to fit into the distribution box on the moving end side and into the control cabinet on the fixed end side. During operation, the sensors continuously check the cables’ transmission properties.

High-frequency technology detects the smallest changes in state without contact

The new generation of igus® monitoring sensor uses high-frequency technology that works without additional sacrificial cores and without contacting existing cores. “This technology allows the sensors to reliably measure even the smallest transmission deteriorations in cables and connectors,” says Richard Habering, head of the igus® smart plastics business unit. This allows effective predictive maintenance in moving industrial applications in which cables and connectors are subjected to continuous mechanical stress.

The new generation of CF.D sensors is compatible with most bus and data cables in the igus® chainflex® cable range. “Condition monitoring enables machinery and equipment users to detect and replace cables approaching their wear limit at an early stage, significantly enhancing plant safety,” Habering said. It is a small investment with a big effect. In some industries, downtime costs of more than $5,600 per minute and more are not uncommon.

i.Cee: plus II: detect impending faults with smartphones and tablets

When data and bus cables approach their wear limit, another innovation comes into play: i.Cee: plus II – a module that connects to the CF.D sensors. A CF.D sensor makes a USB connection to the predictive i.Cee maintenance module. Incipient deterioration of the transmission properties signals necessary maintenance work and adjusts the component service life calculation accordingly. It outputs the measurement results for each individual sensor to a dashboard that users can access through the local network or on the move on the internet with a PC, smartphone, or tablet. Workers responsible for equipment can keep up to date at all times and from anywhere in the world. It also allows them to react quickly to messages received via SMS or e-mail.

The dashboard also provides an overview of the system’s history, including the total number of energy chain strokes, temperature in production, and time remaining until the next scheduled maintenance. Says Habering, “i.Cee: plus II and the new generation of CF.D sensors put predictive maintenance on a secure footing thanks to intuitive operability and flexible integration into user IT so that malfunctions and unexpected operational downtime can be prevented more reliably than ever.” The new generation of CF.D monitoring modules and i.Cee: plus II represent further igus® expansion of the i.Sense environment for predictive maintenance. igus® has been developing a family of products since 2016 under this heading, with various sensors and monitoring modules adding intelligence to motion plastics products such as energy chains, cables, linear guides, and slewing ring bearings. These smart plastics are already predicting the service life for numerous customer applications in such sectors as the automotive industry.