Revolutionizing Urban Mobility: GIKEN’s Automated Underground Bicycle Parking System Employs igus Technology for Enhanced Reliability

Japanese manufacturer GIKEN developed an automated, underground parking system with e-chain® cable carriers from igus®

23 JULY 2024 – An automated underground parking system for bicycles has been developed by the Japanese manufacturer GIKEN, utilizing igus e-chain cable carriers to enhance reliability and maintenance-free operations.

In response to the need for more bicycle parking facilities without altering the cityscape, GIKEN has constructed the ECO Cycle™ garage, which parks bicycles automatically underground. The system’s reliability is ensured by robust energy chains from igus, which guide the lift’s cables.

The shortage of bicycle stands is a common problem faced by many cyclists. The ECO Cycle garage provides a solution by offering automated, underground bicycle parking. Byclists place their bikes at a collection point, after which the system fully automates the parking process, preserving the cityscape.

The ECO Cycle system operates in 63 locations across 26 cities in Japan and is planned to expand to Germany. The process begins with a contact-free check-in via card scanner, followed by the bike being transported into a station, descending underground, and placed onto a bike rack. This process averages 13 seconds per bike.

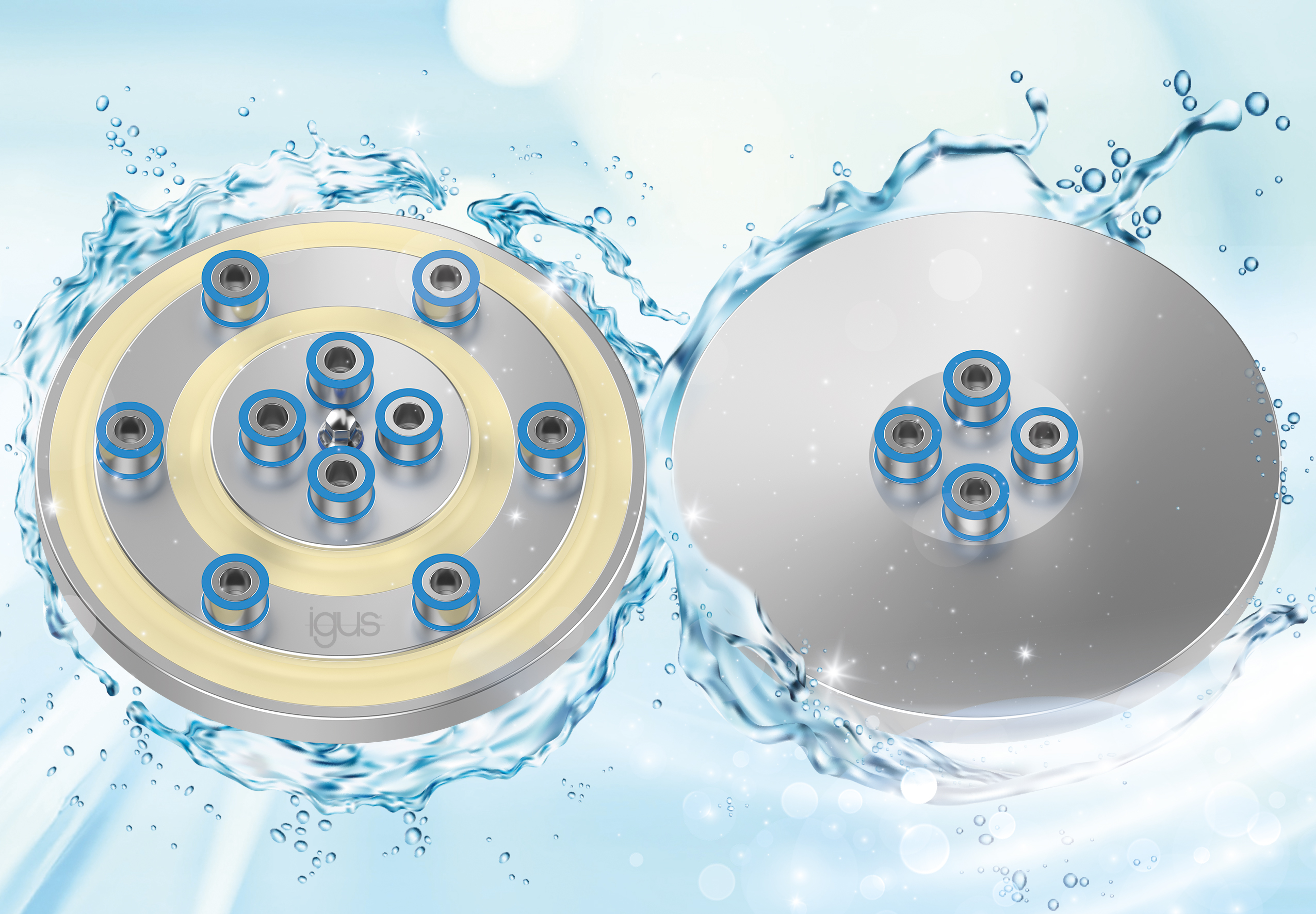

Reliability in automation: cable carriers from igus protect lift cables and withstand 4.5 million operating cycles

The reliability of the automated system is critical, as any malfunction could inconvenience numerous cyclists. Therefore, to protect the lift’s electrical cables, ensure controlled movements, and prevent mechanical damage, GIKEN relies on igus e-chains made of high-performance plastics from the E4.42 and 1400 series.

“The e-chains safeguard the lift’s electrical cables from mechanical damage and external influences, which is crucial for the reliable operation of the entire system,” stated Jörg Ottersbach, Head of the e-chain Business Unit at igus. “Our energy chains are designed to perform up to 4.5 million operating cycles at high speeds and accelerations without any issues.”

The lift operates at a speed of 3m/s with an acceleration of 3m/s², while the telescopic axis reaches 4m/s² with a stroke of 2.6m.

Ottersbach added, “The use of our high-performance plastic e-chains increases the operational safety and efficiency of the ECO Cycle bicycle garages.”