igutex Plain Bearing Technology: Enhanced Reliability with Double Winding

igus Introduces Self-Lubricating and Corrosion-Resistant Polymer Bearings for STS, RTG, and RMG Cranes

June 10, 2024 – The daily operation of STS, RMG, and RTG cranes in ports worldwide involves handling containers under extreme conditions. These cranes often experience premature wear and breakdowns in their wheel and axis units, known as bogies, significantly burdening operators.

Ship-to-shore (STS) cranes, along with rubber-tired gantry (RTG) and rail-mounted gantry (RMG) cranes, operate in harsh environments year-round, including exposure to dirt, dust, salty air, heat, and cold. Bearings in the bogies, which enable the movement of STS cranes weighing several tons along rails, frequently suffer from premature wear.

Uwe Sund, Product Manager for iglide Heavy-Duty Bearings at igus, has observed that such wear often leads to system failures. “Every downtime costs money, consumes time, and is a burden that ports can afford less than ever when handling capacities are high and competitive pressure is increasing,” Sund stated.

igus has introduced a game-changing solution to the issues of traditional steel bearings. The fiber composite bearings from the igutex series offer a robust and wear-resistant alternative that is corrosion-free and resistant to dirt. These plain bearings, made of high-performance plastic, eliminate the need for lubrication, resulting in significant cost savings. With the annual cost of lubrication alone across all industries reaching $ 240 billion, and associated maintenance costs exceeding $200 billion, the benefits of this technology are clear. Self-lubricating plain bearing technology not only reduces maintenance costs but also conserves personnel resources amidst a shortage of skilled labor, and enhances the service life of cranes, thereby increasing port productivity.

Surface Pressures of Up to 29,000 Psi Achieved

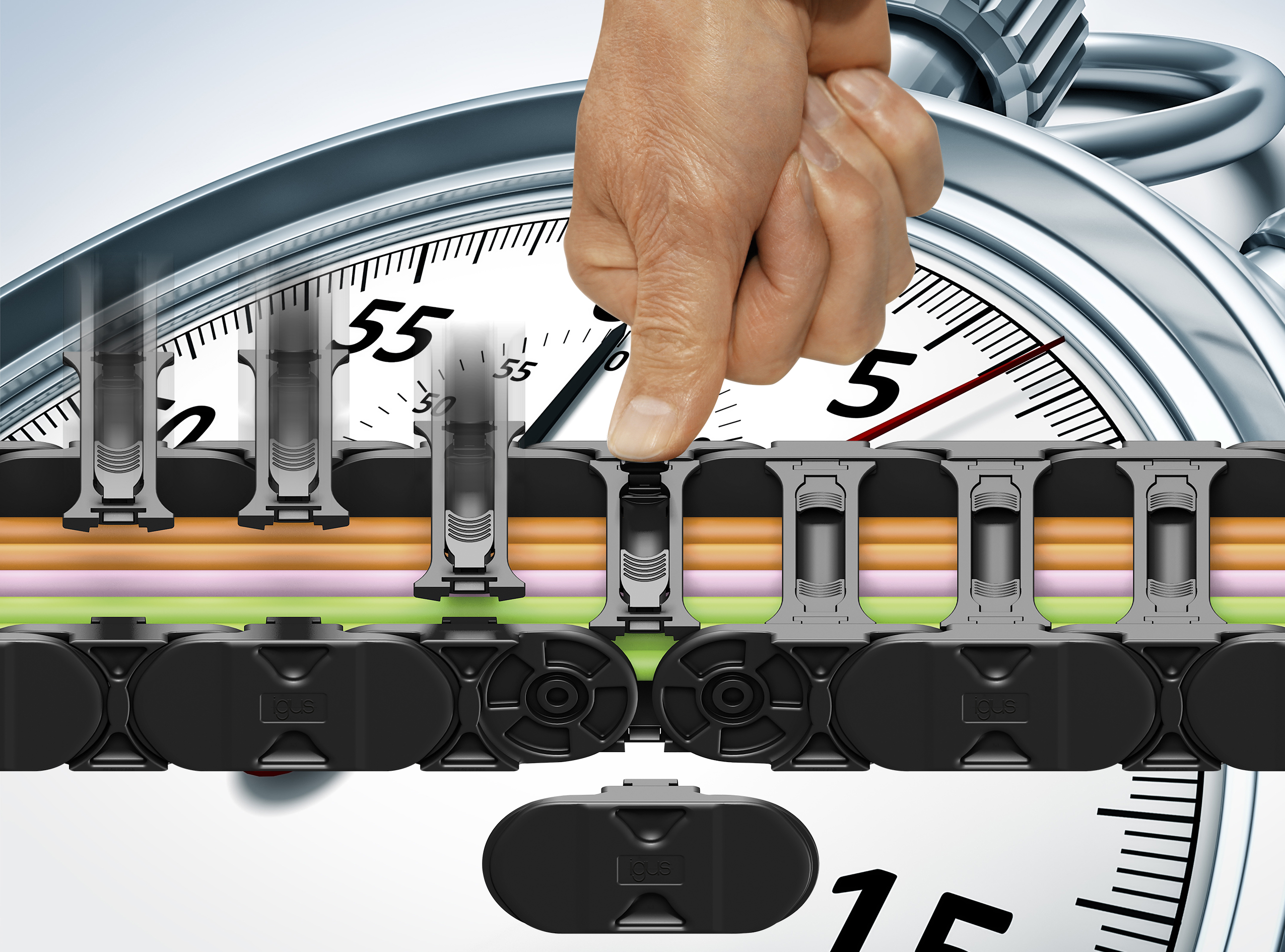

igus manufactures most self-lubricating plain bearings using plastic injection molding. However, the material structure is insufficiently stable for heavy-duty applications such as chassis bearing support for cranes, which experience surface pressures exceeding 11,600 Psi. The igutex composite plain bearings are produced using a two-stage winding process. Initially, an inner layer of filament fabric with integrated solid lubricants is created. These microscopic lubricant particles are gradually released during movement, enabling dry operation with low friction coefficients. The second winding process creates a protective outer shell from a resin-impregnated and highly durable fiberglass fabric.

“Thanks to this two-stage winding process, the polymer bearings in the igutex series achieve a maximum permissible surface pressure of up to 29,000 Psi,” Sund explained. “This ensures that the polymer bearings are robust enough to function in STS cranes with low wear and fail-safe operation.”

Polymer Bearings Outperform Steel and Bronze Bearings in Testing

igus has demonstrated the superior wear resistance of wound polymer bearings compared to steel bearings in its 43,000 ft² test laboratory. Bearings with a diameter and length of 40mm each were subjected to an 11,600 Psi load on a test rig, swiveling 50,000 times by 50° at a speed of 30 swivels per minute. The steel bearing (15MnCr5) exhibited massive shaft wear, leading to test abortion after 10,000 cycles. Similarly, the bronze bearing failed due to wear on the bearing itself. Conversely, the polymer bearing from the igutex series survived 50,000 cycles with only minimal signs of wear.

“These advantages are being recognized by more and more crane manufacturers and operators worldwide,” Sund noted. For example, the Tan Cang Gantry Joint Stock Company (TCGT) from Vietnam is equipping RTG cranes of the current generation with completely lubrication-free and maintenance-free heavy-duty bearings through cooperation with igus Vietnam.

The transition from metal bearings to polymer versions is straightforward for both new and existing crane systems, as igus can manufacture bearings, typically with a diameter of 100mm or more, to identical dimensions. Application consultants are available on-site to assist with conversions.