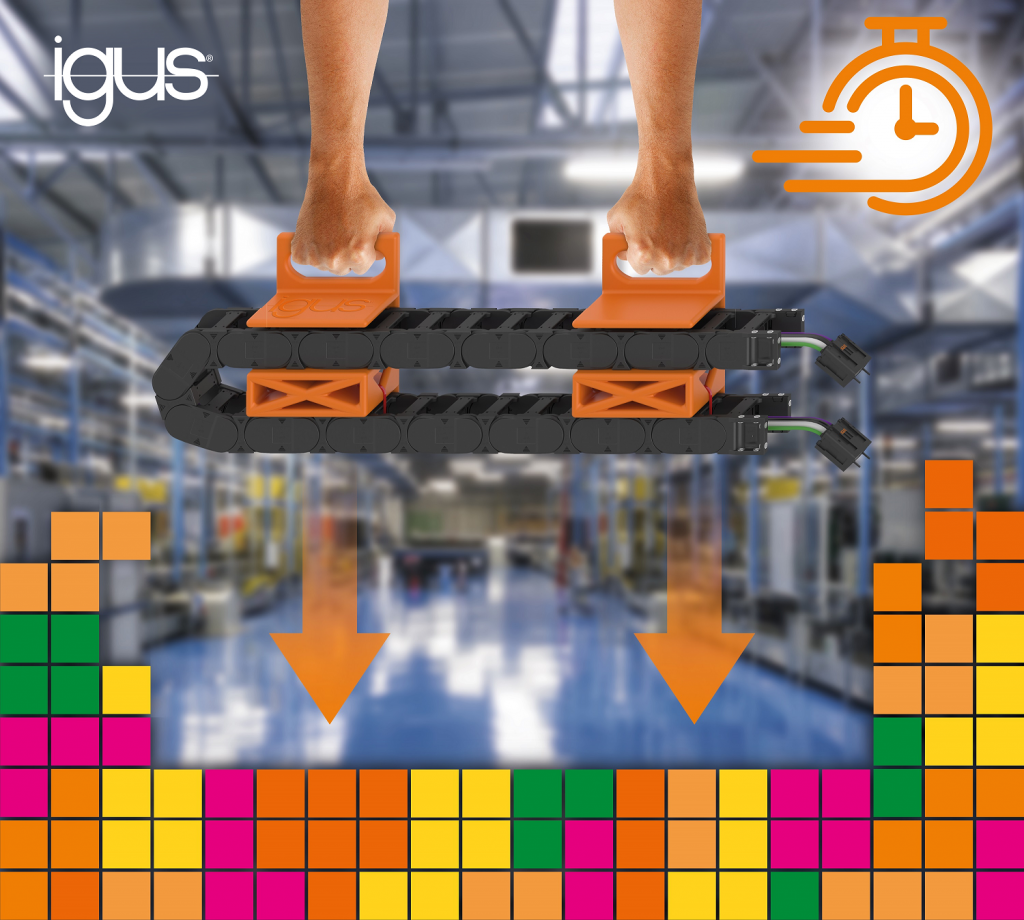

Position ready-to-install e-chain cable carriers easily, quickly, and accurately

The new fast positioner “assembly helper” tool from igus saves installation time and improves handling

November 30, 2023 — igus®, a world leader in motion plastics and moving cable management systems, has introduced the fast positioner assembly helper tool to its readychain service.

Installation downtime is costly for production companies. To simplify and accelerate energy supply system installation for customers, igus offers the readychain® service – pre-assembled e-chain® systems with integrated cables, connectors, and components. This turnkey solution from a single vendor delivers quality-checked, harness-filled e-chains, positioned for easy installation.

igus now complements this offering with the fast positioner assembly tool. By facilitating e-chain handling it further reduces installation time. In an industry where system uptime is imperative, solutions that streamline deployments generate savings and competitive advantages for producers and operators alike.

“This is precisely why we offer our readychain service,” says Markus Hüffel, Product Manager of readychain and readycable at igus.

Customers don’t only benefit when it comes to professional work, such as cutting to length, assembling, and testing the cables. Assembly time is also reduced, which increases productivity.

“It is important to us to deliver not just a product, but a complete solution. We also think about the customer’s upstream and downstream processes and want to actively improve them,” says Markus Hüffel. “For this reason, we have now added a simple tool to our service that offers great added value: the fast positioner. It makes handling and precise positioning of the ready-to-connect energy chain systems even easier, safer, and faster.”

igus delivers readychain systems with the fast positioner already attached in the correct installation orientation. For customers, installation is straightforward: unpack the readychain, position it in place, remove the fast positioner – then the e-chain is ready to connect. The process eliminates the need for additional tools or multiple workers handling the chain. By simplifying and streamlining installation in this way, igus helps customers get up and running faster.

Customized and sustainable solution

“We manufacture the individual parts of the fast positioner using 3D printing. They are tailored precisely to customer requirements, including individual color selection and imprints as an identification aid,” emphasizes Hüffel.

They can be easily placed between the upper and lower parts of an energy chain and fixed in place with cable tie-wraps. Removal after placement is just as simple. In addition, the material can be regranulated and recycled. It is also possible to make the fast positioner from sustainable materials, such as corn starch. The material is both very robust and lightweight. It cannot rust and is compostable, depending on the source material.

Complete solution from a single source

The igus solution provides customers with a single source. igus carries out design, production, and harnessing on site. Hence, throughput times are short, and delivery fast. The fast positioner, the latest addition to the readychain service, is not only a carrying handle but also serves as a fixing device so that the chain is always in the ideal installation position.

“With this tool, we show our customers that we have thought out our solution carefully from start to finish,” concludes Hüffel.

Learn more about readychain® here: https://www.igus.com/info/harnessed-cables-readychain