GMG develops new robot grippers with plastic plain bearings from igus

Lifting a component into a shipping carton with three fingers, then placing cardboard over it for protection with a vacuum gripper: for this automation process, the Gesellschaft für modulare Greifersysteme (GMG) from Soest has developed a multifunctional long arm gripper – with the human hand as a model. How do plastic plain bearings from igus play a vital role in this?

Mohsen Saadat has always been inventive and technically gifted. As a young boy, the 5-year-old Iranian invented his own toys, building small cars out of wire, for example – without any tools. The now 75-year-old’s passion for technology has never left.

At 19, Saadat moved to Germany, studied engineering, and taught as a professor. In 1991, he founded GMG – Gesellschaft für modulare Greifersysteme in Soest, North Rhine-Westphalia. His goal was to combine higher design theory scientific methods with state-of-the-art manufacturing processes.

“Within a few years, we successfully developed lightweight and flexible gripper systems for robots and automation systems based on the human hand,” says Saadat proudly.

He convinced numerous industries of his technology. The grippers, which have up to six individually movable fingers and, in some cases, over 100 joints, are used to handle car wheels in the automotive industry, to hold up sacks when filling them with bulk material, or to package sausage and cheese in the food industry.

A flexible and torsional rigid tower as the long arm of the gripper

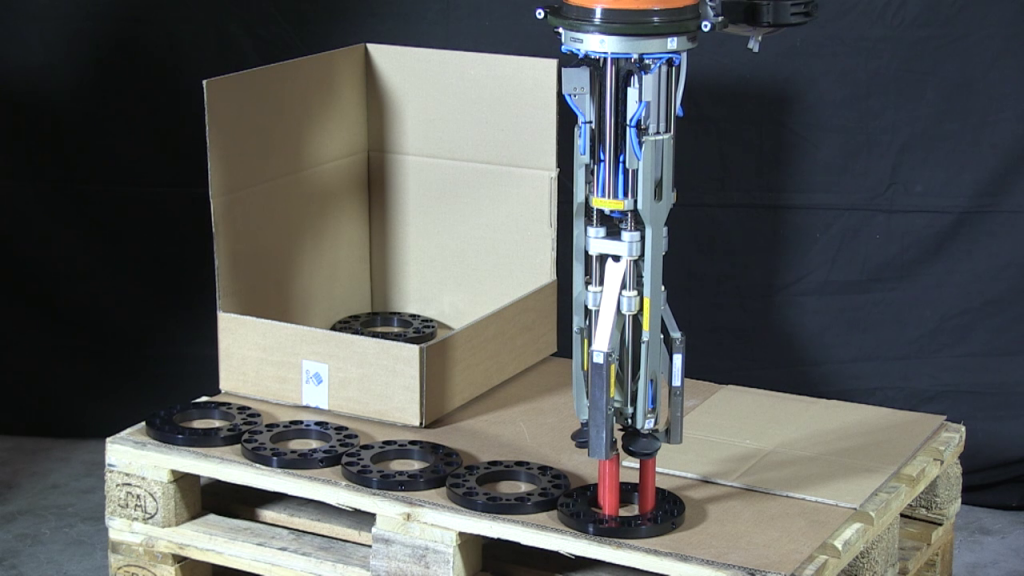

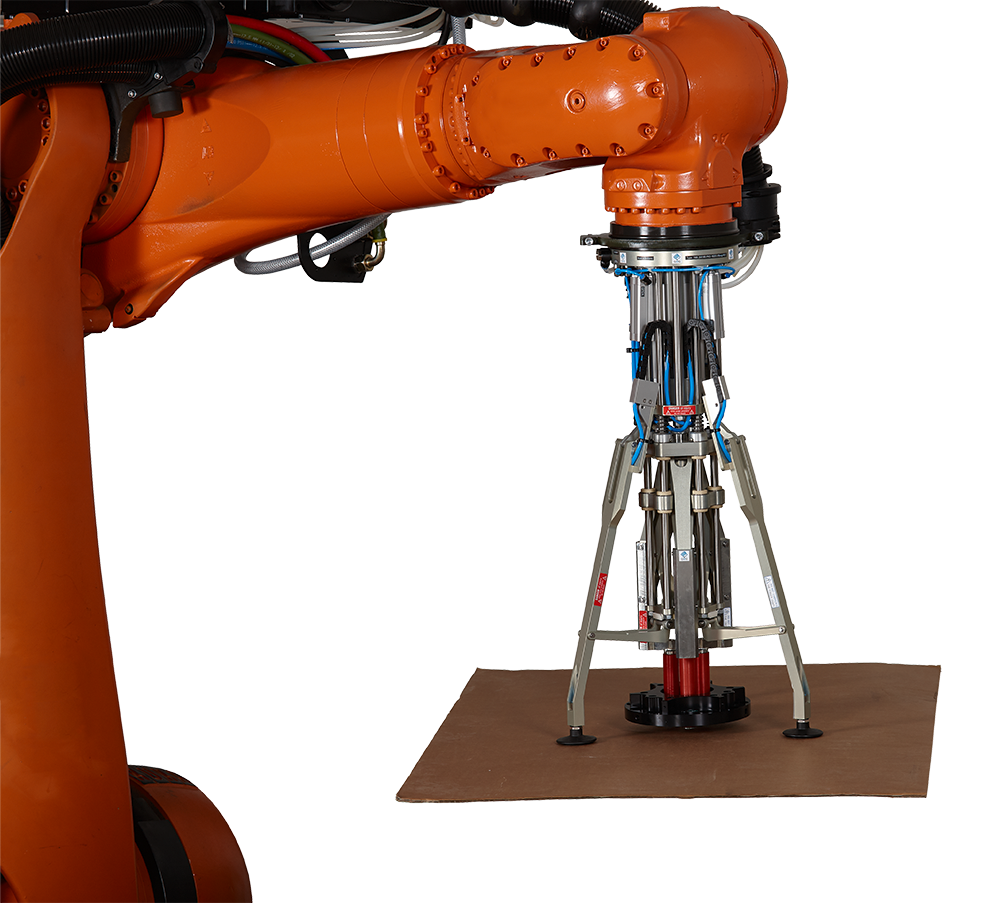

However, one of the inventions that make Saadat proudest is a multifunctional long arm gripper system. The gripper can automatically pack manufactured components – such as brake discs – with three fingers, place them in boxes and then place a layer of protective cardboard over them using a vacuum gripper.

“In this gripper system, a creatively designed, flexible, and torsional rigid tower serves as the long arm of the gripper,” explains Saadat.

“Depending on the task, gripping elements emerge from this tower that mechanically picks up components. After the work is complete, the gripping and suction elements retract to their starting position within the tower.”

Which bearings are suitable for finger joints?

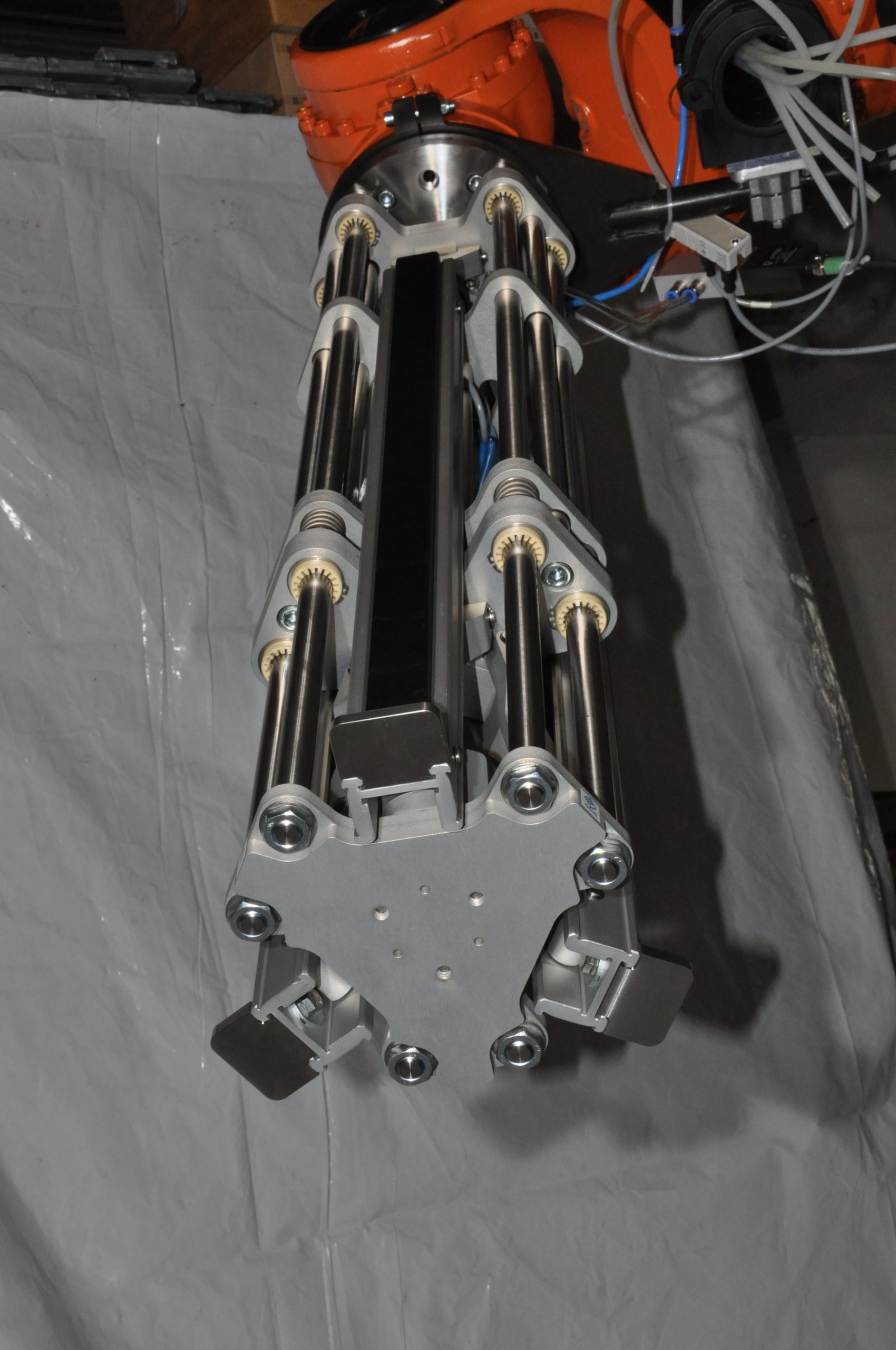

One of the challenges in the development process was to find suitable bearings for the moving metal components of the gripper, such as the finger joints. All the gripper components had to be low-friction, abrasion-resistant, maintenance and lubrication-free, and easy to install. Therefore Saadat quickly ruled out traditional rolling bearings.

“Rolling bearings are suitable for sustained rotational motion. They require the manufacture of more accurate fit, involve complex assembly and disassembly, and result in metallic noise,” stated Saadat.

These disadvantages led Saadat to opt for an alternative: plain bearings made of high-performance plastics from igus – a motion plastics specialist from Cologne that tribologically optimizes plastics for industrial applications.

“We have been relying on plain bearings from igus since 1991. It was, therefore, clear from the outset that the polymer bearings would also be used in the multifunctional long arm gripper. There is virtually no alternative to these bearings for us in automation technology, where there are constant back and forth movements,” says Saadat.

Another advantage is that, compared to traditional metal bearings, the polymer bearings are light, corrosion-free, and maintenance-free. They allow dry operation without needing lubrication, thanks to integrated solid lubricants.

“That’s a critical specification. Because we couldn’t expect our customers to have to lubricate the gripper on a regular basis,” says Saadat.

Virtually no signs of wear after 200,000 cycles

The polymer bearings from igus are so robust that the bearings will outlast a gripper life of around 30 years.

“This is an advantage for our multifunctional gripper, as the maintenance effort is reduced and productivity increases,” continues Saadat.

A test in the igus in-house laboratory also demonstrates how wear-resistant the bearings are. The igus polymer bearings were tested against classic metal bearings in the laboratory. Both bearing types pivoted on a gas-nitrided St52 steel shaft – with a load of 30MPa and a speed of 0.01 meter per second.

“In the case of the metal bearings, the gliding layer was worn after 60,000 cycles,” says Stefan Loockmann-Rittich, head of the iglidur bearings business unit. “The iglide G plain bearings, on the other hand, showed almost no signs of wear even after 200,000 cycles. They are therefore ideally suited for reliable and maintenance-free use over many years.”

Specifications also apply to another bearing used in GMG’s multifunctional gripper. The gripper also uses drylin® R linear bearings, which enable a controlled and safe linear movement of the gripper linkage. “The igus bearings convince us time and again, so we will continue to rely on the iglide polymers in the future,” sums up Saadat.